Fibre to Fabric

Chapter – 3

Handout

Grade VII

Based on NCERT – CBSE Curriculum

Handout Prepared by

Param’s Magazine (www.paramsmagazine.com)

Notes / Handout – Fibre to Fabric – Chapter – 3 – NCERT – CBSE – Class VII

Fabrics

- Fabrics are made from fibres

- Sources of Fibres:

- Natural Fibres

- Plants

- Animals

- Natural Fibres

- Artificial Fibres (Man-made) – known as Synthetic fibres

Types of Fabrics

- Cotton (Cotton Plant – Natural Source)

- Jute (Jute Plant – Natural Source)

- Wool (Animals – Sheep, Goat, Camel, Yak, Angora Goat, Llama, Alpaca – Natural Source)

- Silk (Animal – Silkworm – Natural Source)

- Rayon (Synthetic)

- Nylon (Synthetic)

- Polyester (Synthetic)

Natural Fibres (Plants)

- Cotton (Source: Cotton plant)

- Jute (Source: Jute plant)

Natural Fibres (Animals)

- Wool (Sources: Sheep, Goat, Camel, Yak, Angora Goat, Llama, Alpaca)

- Wool-yielding animals bear hair (fleece) on their body. Woolen fabric is obtained from these hairy fibres.

Sheep

Yak

Camel

Angora Goat

Llama

Alpaca

How does the fleece of wool-bearing animals keeps them warm?

The fleece (hair) of wool-yielding animals traps air, which is a poor conductor of heat. Hence, it keeps these animals warm.

- Silk (Source: Silkworm)

Animals Yielding Wool

Sheep

- The hairy skin of the sheep has two types of fibres, which form its fleece:

- The coarse beard hair

- The fine soft under-hair close to the skin. The fine hair provides the fibres for making wool

- Selective Breeding: Some breeds of sheep having only fine under-hair are bred from selected parents. The process of obtaining offspring with such special characters from selected parents is known as “selective breeding”.

- The wool from the fleece of sheep is available in the market in common.

Yak

- Wool from yak fleece (hair) is common in Tibet and Ladakh

Angora Goat

- Mohair is obtained from angora goats

- Angora goats are found in hilly regions like Jammu and Kashmir

Kashmiri Goat

- The fur (hair) of Kashmiri goat is soft

- Soft shawls like Pashmina shawls are woven from this wool.

Camel

- The camels’ fur is used as wool

Llama

- The fleece from Llama is used as wool

- These animals are found in South America

Aplaca

- Alpaca’s fleece is used as wool

- It is found in South America

From Fibres to Wool

The processes of wool obtained from sheep is explained in this chapter:

- Rearing and breeding of sheep

- Processing fibres into wool

Rearing and breeding of wool

- Regions in India where sheep are commonly reared and bred for obtaining wool:

- The hills in Jammu & Kashmir, Himachal Pradesh, Uttaranchal, Arunachal Pradesh and Sikkim

- The plains of Haryana, Punjab, Rajasthan and Gujarat

- Sheep are herbivores. They prefer grass and leaves

- Shepherds take the herds of sheep for grazing

- Also, sheep are fed on mixture of pulses, corn, jowar, oil cakes (material left out after extracting oil from seeds), and minerals

- They are kept indoors in winter and fed on grains, leaves and dry fodder.

- In order to get good quality wool in large quantities, certain breeds of sheep having thick coat of fur are ‘selectively bred’.

- Once a thick growth of hair is developed in the reared sheep, the hair is shaved off for producing wool.

Indian breeds of sheep

- Lohi

- Good quality wool

- Found in Rajasthan and Panjab

- Rampur bushair

- Brown fleece

- Found in Uttar Pradesh, Himachal Pradesh

- Nali

- For production of Carpet wool

- Rajasthan, Haryana, Punjab

- Bakharwal

- For producing woollen shawls

- Found in Jammu and Kashmir

- Marwari

- Texture: Coarse wool

- Found in Gujarat

- Patanwadi

- For producing hosiery

- Found in Gujarat

Processing Fibres into Wool

We know that wool is used for knitting sweaters and weaving shawls. But, obtaining the final product of wool involves a long process.

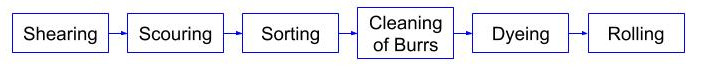

Steps involved in the process of making fibres into wool

- Shearing

- Scouring

- Sorting

- Cleaning of burrs

- Dyeing

- Rolling

Step-1: Shearing

- Shearing is the process of removing the fleece of the sheep along with a thin layer of skin from its body.

- Shearing does not hurt the sheep. Machines similar to the ones used by the barbers are used for shaving off the hair.

- Shearing is done during hot weather. This way, sheep can survive without their protective fur during this period.

- The hair gives woollen fibres, which are processed to obtain woollen yarn.

Shearing does not hurt the sheep. Because, the uppermost layer of the skin is dead. The hair of the sheep grows again as it happens in humans.

Step-2: Scouring

- Removal of grease, dust and dirt by thorough washing of sheared skin with hair

- Manual process of scouring in tanks

- Automated process of scouring using machines

Step-3: Sorting

- The hairy skin is sent to a factory after scouring

- Separation or sorting of the hair of different textures is done from the hairy skin.

Step-4: Cleaning of burrs

- Burrs are the small fluffy fibres in the hair.

- They are picked out from the hair. Later, the fibres are scoured again and dried. As a result, the clean wool is ready to be drwan into fibres.

Step-5: Dyeing

- Natural fleece of sheep is black, brown or white in color.

- The fibres are dyed in various colors.

Step-6: Rolling

- Rolling is the process of straightening, combing and rolling of fibres into yarn.

- The woollen yarn from longer fibres are used for producing sweaters

- The shorter fibers are spun and woven into woollen cloth.

The following video will help you understanding the processing of wool practiced in a factory:

Silk

- Silk fibres are animal fibres

- They are spun by silkworms

- Silk yarn is obtained from the cocoon of the silk moth

- Sericulture: The rearing of silkworkms to obtain silk

Life Cycle of Silk Moth

- Egg: Female silk moth lays eggs

- Silkworm: Eggs hatch larvae called caterpillars or silkworms, which feed on mulberry leaves.

- Pupa:

- Silkworm (caterpillar) spins nets around itself, when it is ready to enter in to the stage of pupa.

- It secretes fibre made of a protein.

- The secreted fibre hardens into silk fibre, when exposed to air. This covering is called cocoon.

- The caterpillar turns into pupa inside the cocoon.

- Moth:

- The pupa develops into moth in the cocoon and comes out of it.

Types of Silk

- Tassar silk

- Moonga silk

- Kosa silk

Silk yarn from different types of silk moths vary depending on their texture (coarse, smooth, shiny, etc). The mulberry moth is the most common moth. Its cocoon yields soft, lustrous and elastic silk fibre.

From Cocoon to Silk

Silk moths are reared and silk is obtained from the cocoons of silkworms

Rearing of silkworms

- A female silk moth lays hundreds of eggs

- The eggs are stored in cloth strips or papers.

- The farmers keep them under hygienic, suitable temperature and humid conditions.

- The eggs are warmed to hatch larvae, by the time the mulberry trees yield fresh crop of leaves. The larvae are also known as caterpillars or silkworms.

- Silkworms are kept in clean bamboo trays, which are filled with freshly chopped mulberry leaves. They eat mulberry leaves 24 hours a day and become fat.

- They stop eating after 25 to 30 days and start spinning the cocoons in the small racks or twigs in the tray.

- The caterpillars transform in to pupae and then in to silk moths inside the cocoons

Silk Processing

- A pile of cocoons are kept under the sun, or boiled or exposed to steam. This is done to separate out the silk fibres.

- Reeling: Reeling is the process of taking out silk threads from the cocoon. Special machines are used to unwind the fibres from the cocoons. Silk thread is obtained after spinning the silk fibres.

- Weavers use these silk threads to weave silk cloth.

The following video will help you understanding the processing of silk practiced in a factory:

Be the first to comment